RESOURCES

These comparisons are general comparisons to give flame workers unfamiliar with Bethlehem torches an idea of the torches flame size and heat capabilities.

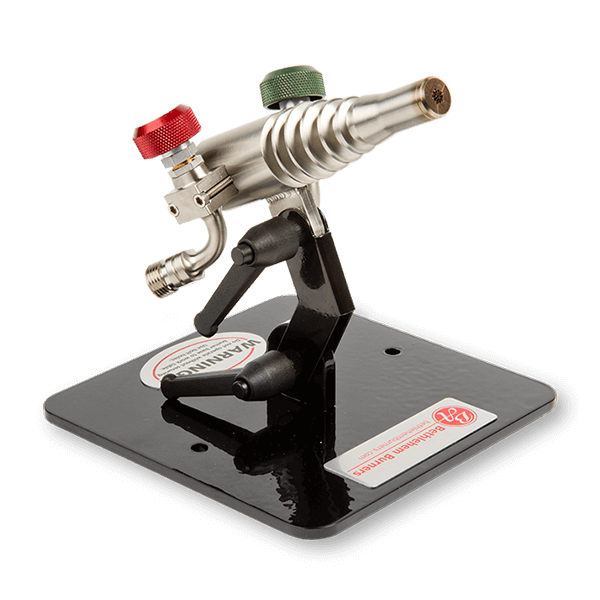

$333

GTT – Lynx

Carlisle – Mini CC

Nortel – Mega Minor

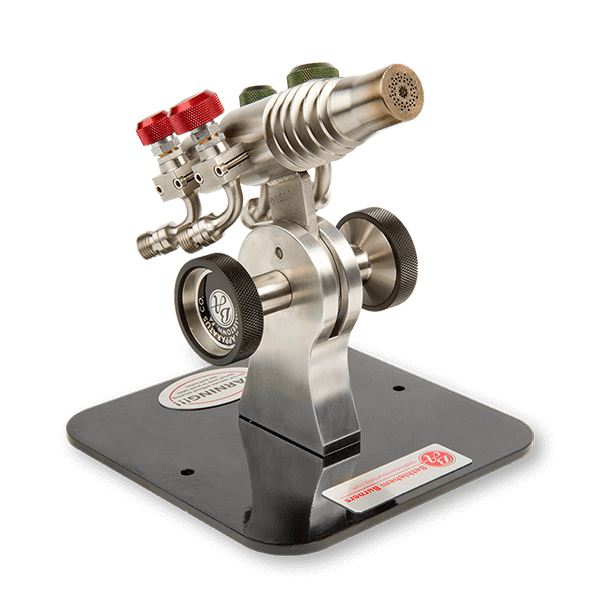

$1,115

GTT – Phantom

Carlisle – CC Black Widow

Nortel – Red Max

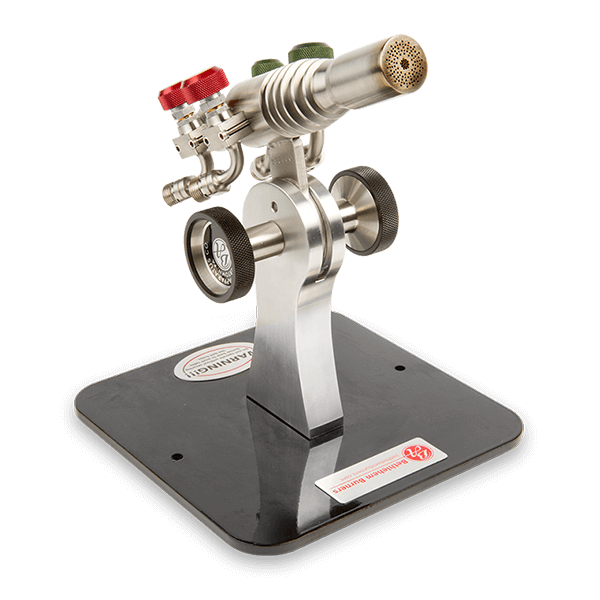

$1,825

GTT – Mirage

Carlisle – CC+

Nortel – Red Rocket

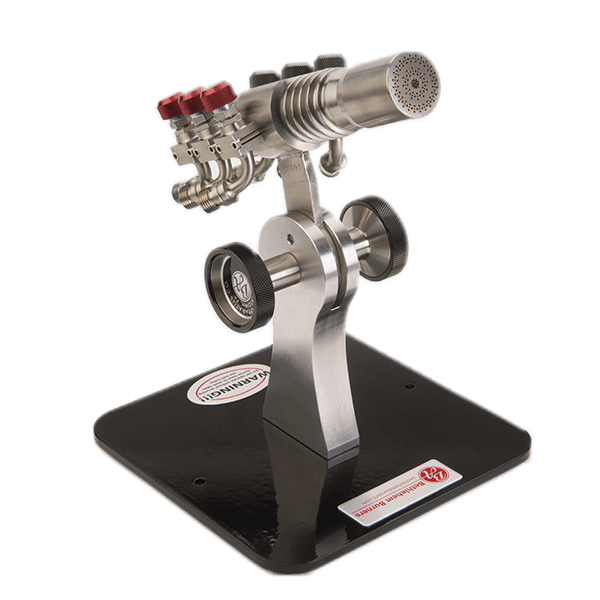

$3,159

GTT – Kabuki

GTT – Delta Mag